Photovoltaic Technologies & Modules: Current Overview

The technologies commonly used in photovoltaic modules are : PERC, TOPCon, HJT, XBC and Tandem Perovskite.

Find out more about the performance and characteristics of each.

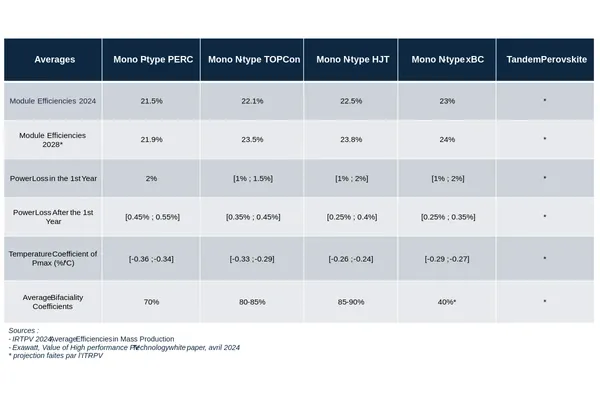

Comparative table of performance by technology:

PERC:

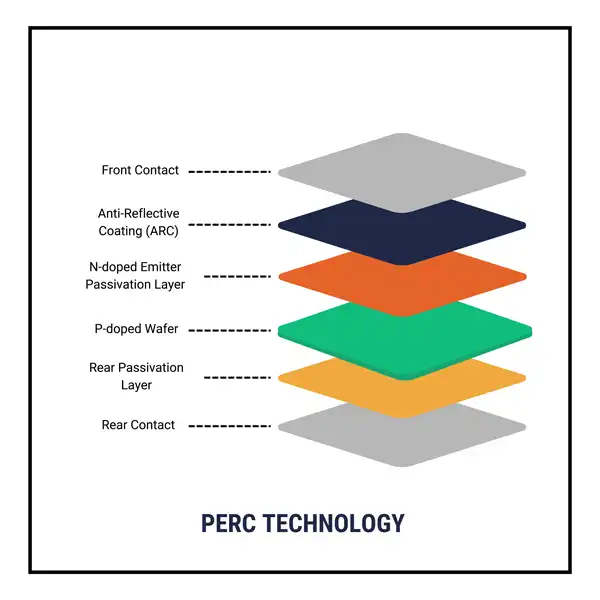

What are the specific features of PERC cells?

The addition of a passivation layer prevents premature recombination of electron-hole pairs, optimizing electricity generation. This type of cell achieves a theoretical surface efficiency of around 24% (in practice, PERC modules rarely exceed 22%).

This technology offers an attractive 'cost-to-energy efficiency' ratio, which has driven its growth over the past five years.

What is the reality in 2024?

PERC remains the most established technology in the industry today, accounting for 62% of the global market share in 2023 (source: ITRPV).

TOPCON

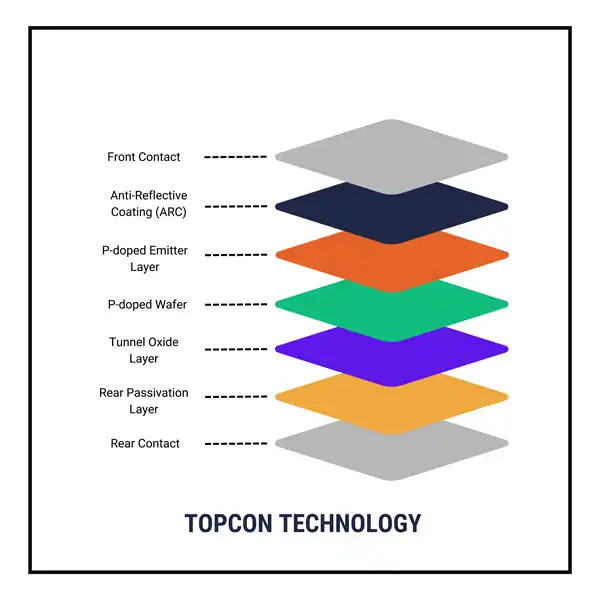

What are the specific features of TOPCon cells?

TOPCon cells differ from PERC cells by incorporating an additional passivation layer: a nanometer-thin silicon oxide layer that reduces unwanted recombination within the cell.

A key feature of this technological evolution is the use of N-type wafers (excess electrons).

In addition to achieving higher efficiency, TOPCon technology offers lower annual degradation rates and better performance at high temperatures.

What is the reality in 2024?

TOPCon technology has replaced PERC cell production, accounting for approximately 80% of monocrystalline modules produced in 2024 (source: ITRPV). This trend is expected to intensify over the next two years.

HJT

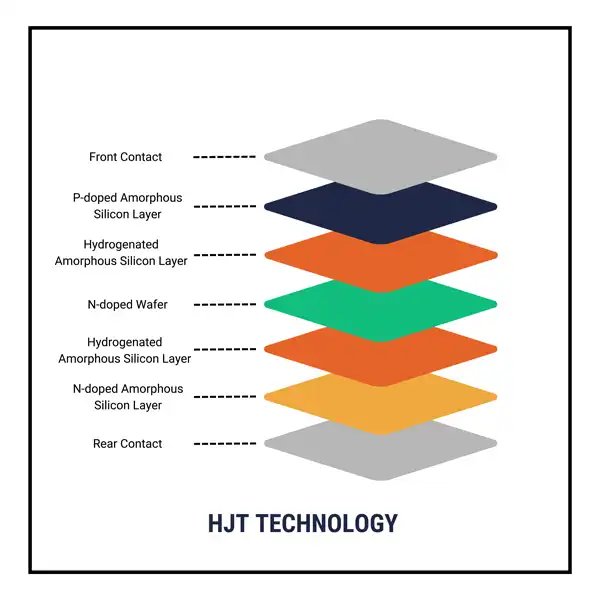

What are the specific features of HJT cells?

HJT technology combines amorphous and crystalline silicon in thin layers, optimizing charge collection and reducing recombination losses. This architecture, with passivation provided by the amorphous silicon, requires specialized manufacturing due to its structural complexity.

HJT technology offers very high bifaciality (>85%) and optimizes losses at high temperatures and low irradiance. Another major advantage of HJT is its reduced carbon footprint, particularly due to the thinner wafers used (100 µm compared to 120-130 µm for TOPCon).

As it requires a different manufacturing process from TOPCon, the production of HJT cells is limited by a lack of industrial investment, which affects its cost.

What is the reality in 2024?

HJT technology accounts for approximately 10% of monocrystalline modules produced in 2024 (source: ITRPV).

The market share of HJT is expected to grow, reaching 20% by 2034, thanks to improved control over the manufacturing chain (source: ITRPV). In the long term, this technology is expected to become more competitive against TOPCon.

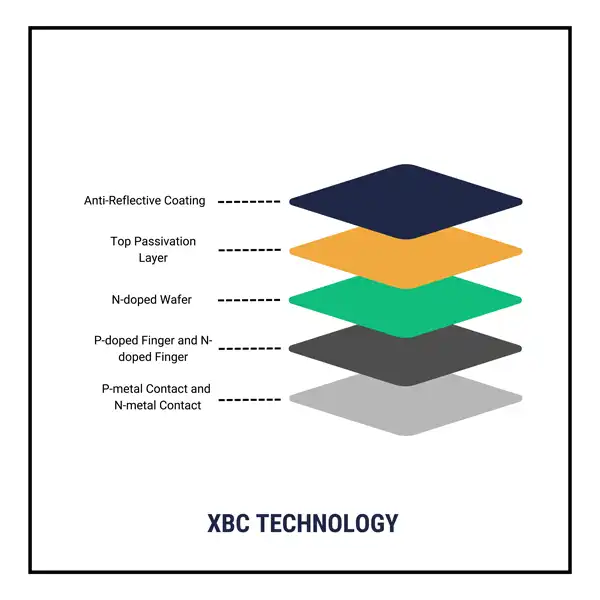

XBC

What are the specific features of XBC cells?

This technology, ideal for rooftop projects, combines aesthetics with high performance. Its back-contact architecture (where electrical contacts are located on the back of the cell) improves surface efficiency by eliminating losses caused by visible metal wires.

Another advantage is that panels using XBC technology are less sensitive to shading. However, bifaciality is limited due to the presence of back contacts.

What is the reality in 2024?

With a limited market share, this architecture is particularly suited for residential rooftop projects. However, its high production cost still restricts its growth in the market.

Most major manufacturers, however, plan to transition to back contact technology within the next 2–3 years to enhance the performance of their modules.

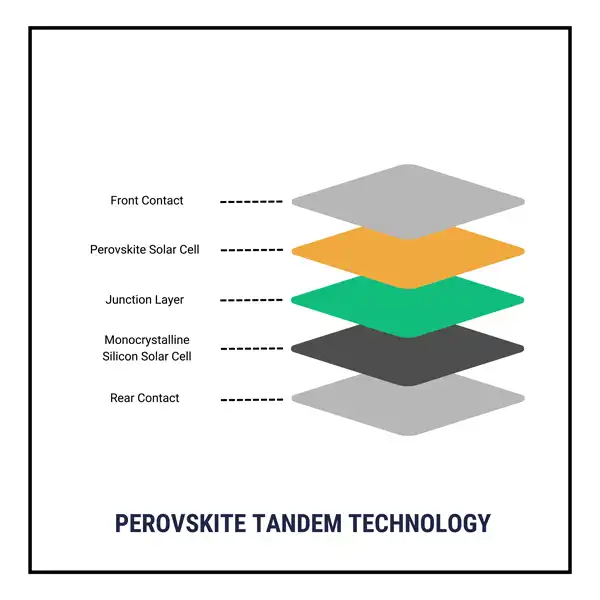

TANDEM PEROVSKITE :

What are the specific features of Tandem Perovskite cells?

Tandem Perovskite technology is characterized by the stacking of two photovoltaic cells.

This architecture represents a breakthrough innovation, with unprecedented theoretical efficiencies (surpassing those observed in the most efficient N-type silicon products on the market). However, Perovskite is sensitive to humidity, raising concerns about maintaining its performance under real-world conditions.

What is the reality in 2024?

The industrialization of this technology is still in its early stages: Oxford PV officially launched the first Tandem Perovskite module sales in September 2024, with an efficiency of 26.9%.

Several manufacturers, including GCL, are investing in this technology, with GCL planning to open a dedicated factory in 2025 (with targeted deliveries by the end of 2025).

In terms of performance, a 34.6% efficiency was achieved in the lab with a Tandem Perovskite cell (June 2024).